- PRE-INSULATION TERMINAL & SCREW ON WIRE CONNECTOR & TOOL

- TERMINAL BLOCK AND BUSBAR TERMINAL

- WIRE CONNECTOR

- CABLE TIE &CABLE CLIP & CABLE GLAND ACCESSORIES

- BUSBAR SERIES AND DIN RAIL

- BUSBAR INSULATOR AND SUPPORT

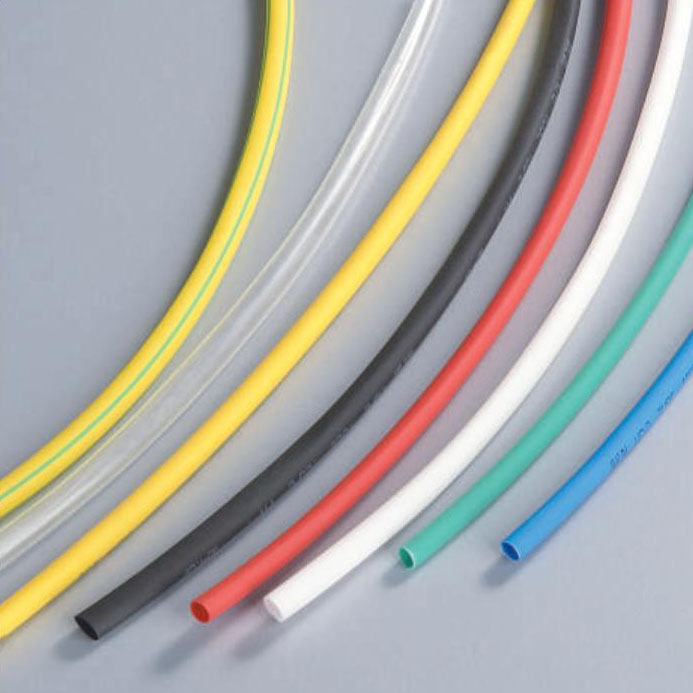

- HEAT SHRINKABLE TUBE

- PUSHBUTTON SWITCH

- INDUSTRIAL PLUG & SOCKET

- WATER PROOF BOX

- PANEL BOX

- JUNCTION BOX (FUSE BOX )

- COPPER AND ALUMINIUM CABLE TERMINAL

- MRK TERMINAL BLOCK

Characteristics

1. HD-1 series non-halogen flame-retardant(environment-friendly)thermal shrinkable bushing boasts very good flame retardation and it does not contain halogenso it will produce no hazardous gases when it is burnt with low smoke and no drop.

2 It does not contain heavy metal and confoms to SGS standard. Safety standard:UL224 VW-1 C-UL CSA C 22.20FT RoHS

Festures and application

1. HD-1 series(non-halogen flame-retardant environment-friendly)thermal shdnkabe bushing uses excellent polymers to mix into the alloy in scientific composition and mechanical mixing.After being shapedthe products continue to undergo the radiation cross-link and continuous expansion with electronic accelerator. The products are characterized by softnessflame retardationfast shrinkage and stable performancewhich are widely used in wire connectionwelding protection. wire end wiring and electronic components protection and insulation treatment;the surface protection of spare parts of body-building equipments and steel structure;rust resistance and treatment of related products;and the marking of electdcal wires and other products.

2. Features

(1)Eight heavy metalsand the halogen passes the SGS inspection.

(2)Not contain organic tin compound [Fentin(Triphenyltin-)-chloride]asbestosAzo compoundsand the matedal restricted for release:formaldehyde.

(3)Application:-40¡æ¡«50¡æ.

(4)Initial shrinkage temperature:70¡æ;super-thin fully shrinkage temperature:105¡æ;and ordinary fully shrinkage temperature:125¡æ.

(5)Softnessflame retardation and good luster.

(6)Complete specifications:§¶0.8-§¶180and special specifications are subject to the orders.

(7)Timely and large quantity of delivery.

(8)Convenient useit can be shrinked after being heated with oven and hot air gun.

(9)The pmduct complles with SonySS-00259EU RoHs and other environmental standards.

Standard color:blackredyellow,greenblue and whiteand special colors are upon the customer' needs.

Performance characteristics

| Performance | Testing method | Indexes | Typical | ||

| Physical characteristics | Mpa Tensile strength Mpa | GB/T1040 | ¡Ý10.4 | 12.6 | |

| Elongation at break% | GB/T1040 | ¡Ý200 | 300 | ||

| Mpa Tensile strengty after thermal ageing Mpa | UL224 158¡æ x 168hr | ¡Ý7.3 | 9.8 | ||

| Elongation at break after thermal ageing% | UL224 158¡æ x 168hr | ¡Ý100 | 300 | ||

| Thermal shock resistance | UL224 158¡æ x 1 hr | Non-sticking | PASS | ||

| Cold bending resistance | UL224 -30¡æ x 1 hr | Non-crack | PASS | ||

| Electrical characteristics | kv/mm Breakdown strength kv/mm | GB1418 | ¡Ý1.5 | 1.8 | |

| Pressure resistance | 150V | U L224 | 1500V non-breakdown | PASS | |

| 600V | U L224 | 2500V non-breakdown | PASS | ||

| Volume resistivity ¦¸.cm | GB1410 | 1x1014 | 1x1015 | ||

| Chemical Characteristics | Corrosion resistance | UL224 158¡æ x 168hr | PASS | ||

| Copper invariability | UL224 158¡æ x 168hr | PASS | |||

| Flame retardation | U L224 | VW-1 | PASS | ||

Environmental protection Characteristics

| Hazardous substance | Test standard | Test result |

| æ€(Cd) | EN1122: 2001 METTHOD B | < 5ppm |

| ãU(Pb) | EPA: METOD 3050B | < 2ppm |

| Ìà(Sb) | EPA: METOD 3052 | < 2ppm |

| ä^(Ba) | EPA: METOD 3052 | < 2ppm |

| ãt(Cr) | EPA: METOD 3052 | < 2ppm |

| ¹¯(Hg) | EPA: METOD 3052 | < 2ppm |

| Éé(As) | EPA: METHOD 3052 | < 2ppm |

| Îø(Se) | EPA: METHOD 3052 | < 2ppm |

| ·úÔªËØ(Fi) | EN 14582 METHOD B | N.D. |

| ÂÈÔªËØ(CI) | EN 14582 METHOD B | N.D. |

| äåÔªËØ(Br) | EN 14582 METHOD B | N.D. |

| µâÔªËØ(I) | EN 14582 METHOD B | N.D. |

HD-1 series Non-halogen flame-retardant(environment-friendly)thermal shrinkable bushing

| Specification | Dimension before shrinking(mm) | Dimension after shrinking (mm) |

Standard packaging (m/disc) |

Application (mm) |

||

| Internal diameter | Wall thickness | Internal diameter | Wall thickness | |||

| ¦µ0.8 | 0.9¡À0.2 | 0.20¡À0.05 | 0.40¡À0.1 | 0.32¡À0.05 | 200 | 0.6¡«0.8 |

| ¦µ1.0 | 1.2¡À0.3 | 0.20¡À0.05 | 0.48¡À0.1 | 0.32¡À0.05 | 200 | 0.75¡«0.9 |

| ¦µ1.5 | 1.7¡À0.3 | 0.20¡À0.05 | 0.73¡À0.1 | 0.32¡À0.05 | 200 | 0.95¡«1.4 |

| ¦µ2.0 | 2.2¡À0.3 | 0.25¡À0.05 | 0.98¡À0.1 | 0.32¡À0.05 | 200 | 1.1¡«1.8 |

| ¦µ2.5 | 2.6¡À0.3 | 0.25¡À0.05 | 1.23¡À0.2 | 0.35¡À0.05 | 200 | 1.35¡«2.3 |

| ¦µ3.0 | 3.2¡À0.4 | 0.25¡À0.05 | 1.45¡À0.2 | 0.35¡À0.05 | 200 | 1.6¡«2.7 |

| ¦µ3.5 | 3.6¡À0.4 | 0.25¡À0.05 | 1.72¡À0.2 | 0.35¡À0.05 | 200 | 1.85¡«3.2 |

| ¦µ4.0 | 4.2¡À0.4 | 0.25¡À0.05 | 1.96¡À0.2 | 0.35¡À0.05 | 200 | 2.1¡«3.6 |

| ¦µ4.5 | 4.6¡À0.4 | 0.25¡À0.05 | 2.20¡À0.2 | 0.35¡À0.05 | 200 | 2.35¡«4.0 |

| ¦µ5.0 | 5.2¡À0.4 | 0.25¡À0.05 | 2.48¡À0.2 | 0.35¡À0.05 | 200 | 2.6¡«4.5 |

| ¦µ6.0 | 6.2¡À0.4 | 0.28¡À0.15 | 2.96¡À0.3 | 0.45¡À0.15 | 200 | 3.1¡«5.4 |

| ¦µ7.0 | 7.2¡À0.4 | 0.28¡À0.15 | 3.48¡À0.3 | 0.45¡À0.15 | 100 | 3.7¡«3 |

| ¦µ8.0 | 8.2¡À0.5 | 0.28¡À0.15 | 3.95¡À0.3 | 0.45¡À0.15 | 100 | 4.2¡«7.2 |

| ¦µ9.0 | 9.2¡À0.5 | 0.30¡À0.15 | 4.40¡À0.3 | 0.50¡À0.15 | 100 | 4.7¡«8.0 |

| ¦µ10 | 10.2¡À0.5 | 0.30¡À0.15 | 4.90¡À0.3 | 0.50¡À0.15 | 100 | 5.2¡«9.0 |

| ¦µ11 | 11.2¡À0.5 | 0.30¡À0.15 | 5.40¡À0.3 | 0.50¡À0.15 | 100 | 5.7¡«10 |

| ¦µ12 | 12.2¡À0.5 | 0.30¡À0.15 | 5.90¡À0.5 | 0.50¡À0.15 | 100 | 6.2¡«11 |

| ¦µ13 | 13.2¡À0.5 | 0.33¡À0.15 | 6.40¡À0.5 | 0.50¡À0.15 | 100 | 6.7¡«12 |

| ¦µ14 | 14.2¡À0.5 | 0.35¡À0.15 | 6.90¡À0.5 | 0.50¡À0.15 | 100 | 7.3¡«13 |

| ¦µ15 | 15.2¡À0.6 | 0.38¡À0.15 | 7.40¡À0.5 | 0.60¡À0.15 | 100 | 7.8¡«14 |

| ¦µ16 | 16.2¡À0.6 | 0.38¡À0.15 | 7.90¡À0.5 | 0.60¡À0.15 | 100 | 8.3¡«15 |

| ¦µ17 | 17.2¡À0.6 | 0.38¡À0.15 | 8.40¡À0.5 | 0.60¡À0.15 | 100 | 8.8¡«16 |

| ¦µ18 | 18.2¡À0.6 | 0.40¡À0.15 | 8.90¡À0.5 | 0.60¡À0.15 | 100 | 9.3¡«17 |

| ¦µ20 | 20.2¡À0.8 | 0.40¡À0.20 | 9.90¡À0.5 | 0.70¡À0.20 | 100 | 11.4¡«19 |

| ¦µ22 | 22.2¡À0.8 | 0.42¡À0.20 | 10.80¡À1.0 | 0.70¡À0.20 | 100 | 12.4¡«21 |

| ¦µ25 | 25.3¡À0.8 | 0.45¡À0.20 | 12.30¡À1.0 | 0.70¡À0.20 | 50 | 12.8¡«24 |

| ¦µ28 | 28.3¡À0.8 | 0.45¡À0.20 | 13.50¡À1.0 | 0.70¡À0.20 | 50 | 14.4¡«29 |

| ¦µ30 | 30.2¡À0.8 | 0.45¡À0.20 | 14.70¡À1.0 | 0.70¡À0.20 | 50 | 16¡«29 |

| ¦µ35 | 35.2¡À0.8 | 0.50¡À0.20 | 17.30¡À1.0 | 0.80¡À0.20 | 50 | 18¡«34 |

| ¦µ40 | 40.0¡À1.0 | 0.50¡À0.20 | 19.80¡À1.0 | 0.80¡À0.20 | 50 | 21¡«39 |

| ¦µ50 | 50.0¡À1.0 | 0.50¡À0.20 | 24.80¡À1.0 | 0.80¡À0.20 | 50 | 26¡«49 |

| ¦µ60 | 60.0¡À1.0 | 0.60¡À0.20 | 29.80¡À1.0 | 0.80¡À0.20 | 25 | 35¡«55 |

| ¦µ70 | 70.0¡À1.0 | 0.65¡À0.20 | 34.00¡À2.0 | 1.00¡À0.20 | 25 | 40¡«65 |

| ¦µ80 | 80.0¡À1.0 | 0.65¡À0.20 | 39.00¡À2.0 | 1.00¡À0.20 | 25 | 45¡«75 |

| ¦µ90 | 90.0¡À1.0 | 0.65¡À0.20 | 44.00¡À2.0 | 1.00¡À0.20 | 25 | 50¡«88 |

| ¦µ100 | 100.0¡À2.0 | 0.65¡À0.20 | 49.00¡À2.0 | 1.00¡À0.20 | 25 | 55¡«95 |

| ¦µ120 | 120.0¡À2.0 | 0.70¡À0.20 | 59.00¡À2.0 | 1.20¡À0.20 | 25 | 65¡«115 |

| ¦µ150 | 150.0¡À2.0 | 0.70¡À0.20 | 74.00¡À2.0 | 1.20¡À0.20 | 25 | 80¡«145 |

| ¦µ180 | 180.0¡À2.0 | 0.70¡À0.20 | 88.00¡À2.0 | 1.20¡À0.20 | 25 | 95¡«175 |